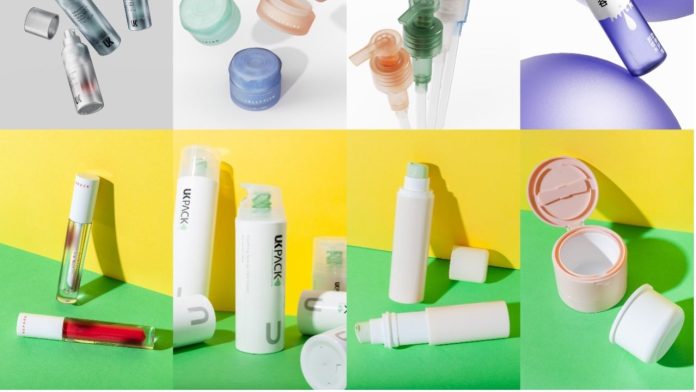

In the modern competitive market of beauty and personal care products and services, packaging is significantly larger than just a container. It influences brand image, user experience, cost control, and speed to market. A one-stop packaging supplier like UKPACK cosmetic packaging is a firm that handles all packaging processes under one roof, including engineering and design, manufacturing, decorating, quality control, and delivery. Companies do not collaborate with different suppliers and find a partner who will take control of the entire process.

Simplified Communication and Clear Accountability

Among the largest benefits of collaborating with a one-stop packager is the ease of communication. In many cases where there is a group of suppliers, there is a possibility of losing information between designers, mold makers, decorators, and factories. This tends to cause delays, miscommunication, or quality problems. The communication within the company is more straightforward and effective, as there is only one supplier. Accountability is also evident in the sense that the supplier is absolutely accountable to timelines, quality, and outcome as opposed to passing the buck to various stakeholders.

Faster Development and Shorter Time to Market

The pace when it comes to product launch is very crucial, e.g., in such a business as cosmetics, the trends evolve rapidly. One-stop packaging providers are capable of saving a considerable amount of time in terms of development since the process of design, prototyping, tooling, and production is arranged in-house. Since teams operate closely, the process of making decisions becomes quicker, and the problems are detected at the initial stage. Quick prototyping and sampling enable the brands to take a look and make changes to the design earlier, before the products end up in the market out of time, and cause avoidable delays in reaching the intended market.

Consistent Quality Across All Components

The quality of packaging is determined by the quality of the fit and functionality of the various components. In case bottles, pumps, caps, and decoration are made by various manufacturers, the differences become more probable. The materials, dimensions, tolerances, and finishes of all parts are regulated by a single supplier. This creates uniformity in the quality produced in one batch to the next, and the packaging, which is approved in the samples, gets to the warehouse. Quality and reliability will also minimize product returns, loss of leakage, and damage that occur during transportation.

Stronger Technical and Engineering Support

Packaging does not simply have to do with appearance. It should be adaptable to the formulas, filling lines, storage conditions, and regulations. A one-stop supplier of packaging offers engineering services and technical support throughout the project. The selection of the material, structure design, wall thickness, and dispensing systems can be advised by engineers to ensure that the performance and durability are guaranteed. Such technical advice will keep brands out of expensive errors, including selecting packaging that is reactive toward the formula or that fails to work.

Improved Flexibility and Easier Customization

Brands usually require packaging that is an identity and one that can be distinguished on the shelf. The customisation is more flexible when having a one-stop supplier. Internal designs, surface finishing, color modification, and decoration modification can be managed without the need to go through a lengthy coordination process. This is particularly beneficial to limited editions, seasonal releases, or extended product lines that are to be branded uniformly across various formats.

Reduced Risk and Smoother Project Management

Packaging projects are characterized by numerous moving components, including the development of the molds, their quality testing, and logistics. An integrated packaging vendor has organized project management to have everything in check. Specialized project managers facilitate schedules, authorization, and manufacturing processes and spot the risks at an early stage. Whenever problems occur, solutions are made within a very short time since all the teams are collaborating. Such a proactive strategy minimizes the chances of lateness, quality breakdowns, and late changes.

Long-Term Partnership and Brand Growth

In addition to single projects, a one-stop packaging supplier will not be a one-time vendor, but will be a long-term partner. The supplier will be able to make better recommendations as time goes by, as he gets to learn more about the products, markets, and objectives of the brand. This joint venture helps in uniform packaging innovation, easier line extensions, and more assured expansion as the brand expands.

Conclusion

Cooperation with a one-stop provider of packaging has obvious efficiency, quality, cost management, and reliability benefits. Brands are able to enjoy quicker launches, reduced risk, and better packaging performance through managing design, engineering, manufacturing, and support within one system. In order to enhance and reduce the complexity of operations, while ensuring a high level of standards, a one-stop packaging solution is a viable and strategic benefit in a highly competitive business world.